Konica – KM1024

*100% achievement in large printings combination, compared with some small printers, S1024 can feed media which thickness is above 0.44mm withoutskidding, and in feeding smooth-sided banner, S1024 can ensure accurate feeding step with good printing quality and high precision combination

*For high viscosity media, the feeding structure of traditional small printer is difficult to peel the media during feeding but S1024 can be easily qualified

*Intelligent infrared heating system to dry picture fast

*Front and rear electrical press wheel, automatic station for printhead protection

Hardware functions and deployments

*Advanced servo motor for feeding&collecting system

* Integral machine body with higher accuracy of feeding and collecting

* Unique printhead protection stack

* Secondary ink tank and ink circuit heating system

* Three-stage adjustable temperature heating for media

* Reserved suction outlet for automatic printhead cleaning

* LED lights the printing bed for better observing printing quality and color bar

Advantage for using KM1024 print heads

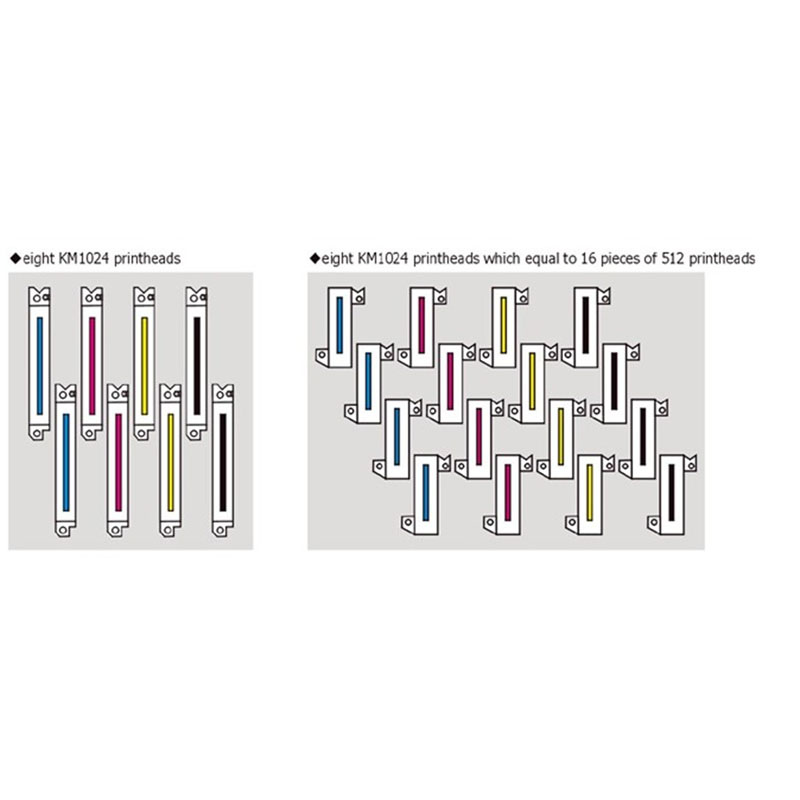

*KM1024 printheads has 1024 nozzles which equal to two KM512 printheads or eight 128 printheads,

higher printing speed with less printheads

*With less printheads, physical position can be easily and accurately calibrated, which can avoid the deviation in physical calibration compared with more printheads, then the printing quality can be entirely enhanced

*KM1024 printhead can improve the printing quality obviously when prints on back-litbanner,

pvc vinyl and some special colors, which can meet the requirement of high-end clients